1 x Cincinnati FTV 850-1800 CNC travelling column vertical machining centre with automatic tool changing BT50 taper, rigid tapping and through spindle coolant. Fourth axis enabled. Traverses X = 1800mm (or 2 x 750mm), Y = 850mm, Z = 800mm. Purchased new 2005

1 x Haas VF-2DSE CNC vertical machining centre with automatic tool changing, rigid tapping, through spindle coolant, Renishaw probing system and 4th axis. Traverses X = 762mm, Y = 406mm, Z = 508mm. Purchased new 2008.

CNC Capacity List

Cincinnati FTV 850-1800

Haas VF-2DSE

Doosan 2600Y

1 x Doosan 2600Y. Bar feed capacity = 65mm, chuck capacity = 254mm, swing 525 mm, 760mm Z Length,

+- 102mm Y axis , Purchased new August 2011

+- 102mm Y axis , Purchased new August 2011

1 x Doosan 2600M. Bar feed capacity = 76mm, chuck capacity = 254mm, swing 525 mm, 760mm Z Length,

, Purchased new February 2012

, Purchased new February 2012

Doosan 2600M

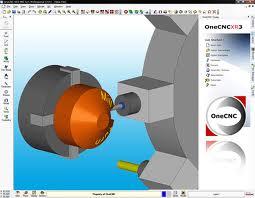

ONECNC CAD/CAM CNC Software

We can work straight from solid model, STP,IGES file and virtual cut Material before

Actual machining.

We can work straight from solid model, STP,IGES file and virtual cut Material before

Actual machining.

1 x Mazak CNC Vertical Machining Centre 820-30HD

(Heavy Duty)

Traverses – X = 3000mm, Y = 820mm, Z = 870mm

36 Tools BT50

10,000 RPM Spindle

Purchased new 2015

Fitted with ABB Robot loading

(Heavy Duty)

Traverses – X = 3000mm, Y = 820mm, Z = 870mm

36 Tools BT50

10,000 RPM Spindle

Purchased new 2015

Fitted with ABB Robot loading

Mazak CNC Vertical Machining Centre 820-30HD (Heavy Duty)

1 x Doosan Puma CNC 480 Large Bore Lathe

Max. Turning Dia 650mm

Max. Turning Length 992mm

Max. Between Centres 1135

Max. Bore Diameter 263mm

Purchased new 2015

Max. Turning Dia 650mm

Max. Turning Length 992mm

Max. Between Centres 1135

Max. Bore Diameter 263mm

Purchased new 2015

Doosan Puma CNC 480 Large Bore Lathe

1 x Doosan DNM750 II.

Doosan DNM750 II

1 x Doosan Puma GT-2600.

Doosan Puma GT-2600

Dugard HD1886B

1 x Dugard HD1886B

Traverse X 1800mm

Traverse Y 860mm

Traverse Z 700mm

Tools 24 x BT50

6000 RPM Spindle

Traverse X 1800mm

Traverse Y 860mm

Traverse Z 700mm

Tools 24 x BT50

6000 RPM Spindle

ENS Facility from 2018

Light fabrication facility equipped for MIG and arc welding.

In 2005 the company moved into a brand new 12,000 sq. ft.(1140 sq. mtr.) unit and the workshop is equipped with electric overhead cranes, magnetic lifters, magnetic work holding fixtures, a toolroom lathe, pedestal drills and a 2500kg capacity fork lift truck (new 2007), ICI Cleanline 2 ultrasonic parts washer.

The company has a Fully equipped Temperature Control Inspection Room including our C.M.M a 1.6M x 1M surface table with a Moore and Wright digital height gauge, a vast array of micrometers, bore micrometers and Verniers and is accredited to BS EN ISO 9001-2008.

In 2005 the company moved into a brand new 12,000 sq. ft.(1140 sq. mtr.) unit and the workshop is equipped with electric overhead cranes, magnetic lifters, magnetic work holding fixtures, a toolroom lathe, pedestal drills and a 2500kg capacity fork lift truck (new 2007), ICI Cleanline 2 ultrasonic parts washer.

The company has a Fully equipped Temperature Control Inspection Room including our C.M.M a 1.6M x 1M surface table with a Moore and Wright digital height gauge, a vast array of micrometers, bore micrometers and Verniers and is accredited to BS EN ISO 9001-2008.

ENS Precision Engineering

UK Office

Unit 1 Barbados Way,

Hellaby Industrial Estate,

Hellaby

Rotherham

S668RX

Email: sales@ens-precision.co.uk

Tel: +44(0) 1909 551133

Fax: +44(0) 1909 551123

Atwell Engineering Holdings Ltd. Registration No. is 3250952

UK Office

Unit 1 Barbados Way,

Hellaby Industrial Estate,

Hellaby

Rotherham

S668RX

Email: sales@ens-precision.co.uk

Tel: +44(0) 1909 551133

Fax: +44(0) 1909 551123

Atwell Engineering Holdings Ltd. Registration No. is 3250952